RICHARDS BAY (miningweekly.com) – The new automation at Richards Bay Coal Terminal (RBCT) in KwaZulu-Natal has begun with very efficient coal stacking and reclaiming processes that have millimetre accuracy.

The stacker reclaimer, with no onboard operator, calculates the most productive way to stack coal while operators oversee the process safely from a central control room.

Rather than air digging in and out of coal, the machine finds the most optimal way of continuously remaining in coal.

Digging efficiency is already up by 6.2% and electricity consumption, fuel use and dust emissions are down.

By introducing Africa's first fully autonomous stacker reclaimer, RBCT is adhering to international best practices and securing long-term competitiveness

“We have the potential, we believe, to probably achieve around 8% to 10% improvement overall,” RBCT GM asset management Kubendren Naidoo outlined to visiting journalists during this week’s media briefing attended by Mining Weekly.

“We’re in the process of further finetuning and optimising the project of machines while we roll out phase two, which is being approved for four machines in the current year.

“We have the skills, the knowledge and the capabilities within the terminal which set the detailed specifications, methodologies and requirements and we were on time and under budget.

“We took two weeks to roll out the technology on the machine, and a further two weeks to commission and optimise the machine,” Naidoo pointed out.

This year’s phase 2 involves four stacker-reclaimer machines and the autonomous stockyard machine rollout plan for phase 3 in 2027 and phase 4 in 2028 has already been outlined.

“Our commitment to our employees is that we will not retrench anybody as a result of automation,” RBCT CEO Alan Waller emphasised.

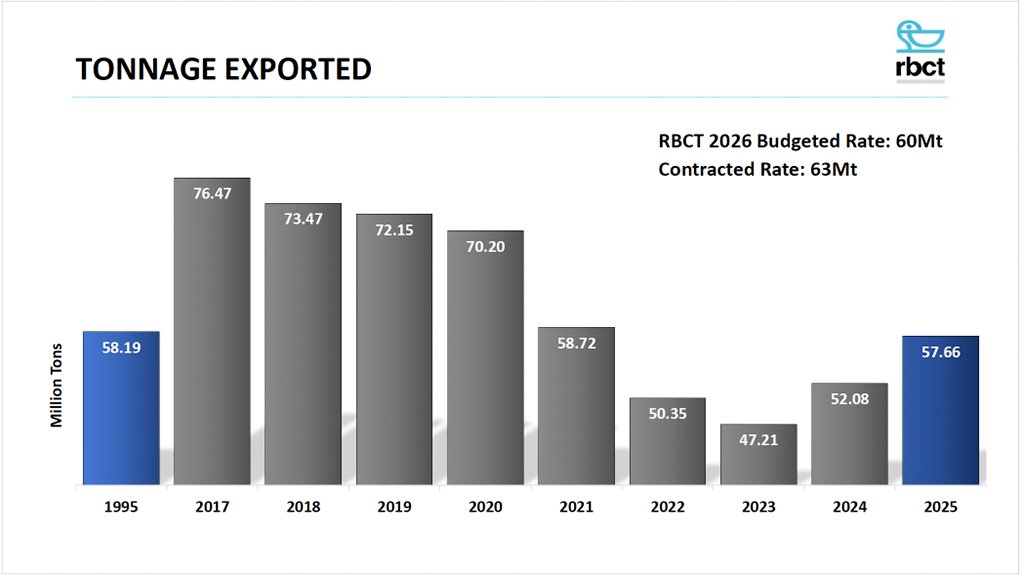

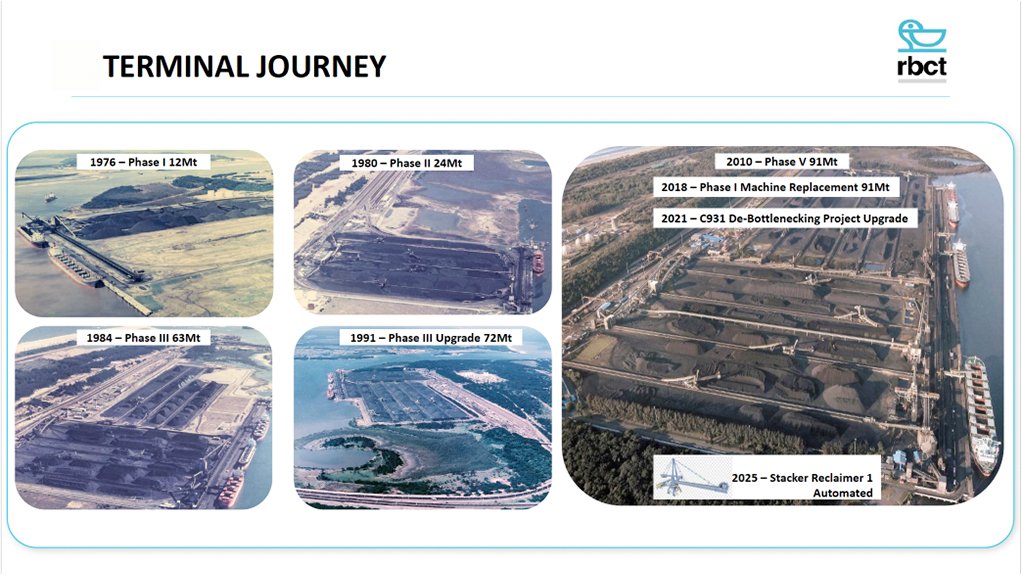

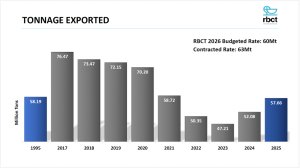

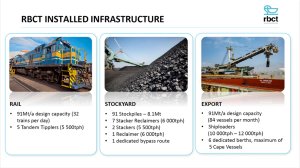

Established in 1976, RBCT turns 50 on April 1 as Africa’s single largest coal terminal. With a 91-million-ton-a-year capacity, RBCT last year exported a 10%-plus higher 57.66-million tons of coal and its budgeted rate for 2026 is 60-million tons and contracted rate 63-million tons.

“We’re always trying to look at smarter, better, faster ways of handling coal to make sure we are a company of choice,” said Naidoo.

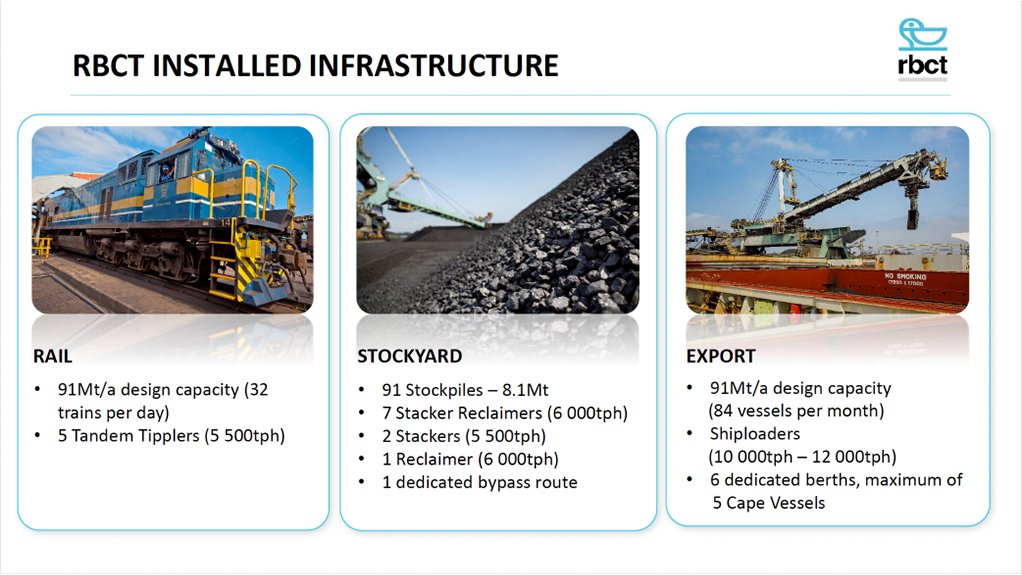

Coal is received from 69 coal mines for offloading, stockpile managing and vessel loading by RBCT with Transnet National Ports Authority seeing to the berthing of 84 vessels a month.

In 2025, 7 157 trains offloaded at RBCT and the average of 23 trains a day from December 20 to January 18 is reflecting a positive upward trend.

Train turnaround time is also showing improvement.

EMAIL THIS ARTICLE SAVE THIS ARTICLE ARTICLE ENQUIRY FEEDBACK

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here