JOHANNESBURG (miningweekly.com) – A robotic rig deployed at a project last year increased productivity by about 50% and consumed 75% less water than the more conventional rigs working on the same contract, Master Drilling director Koos Jordaan reported this week.

An image showing the robotic arm of the rig was displayed during this week’s presentation of dividend-yielding, record $270.8-million revenue financial results for the 12 months to December 31.

In addition, Master Drilling’s slim drilling robotic rig is moving to field trials in the second quarter of this year.

Interestingly, a company-developed slot-boring rig is being commissioned for larger-diameter boxholes, and a low-profile rig is on a contract in Tanzania after being made available commercially last year.

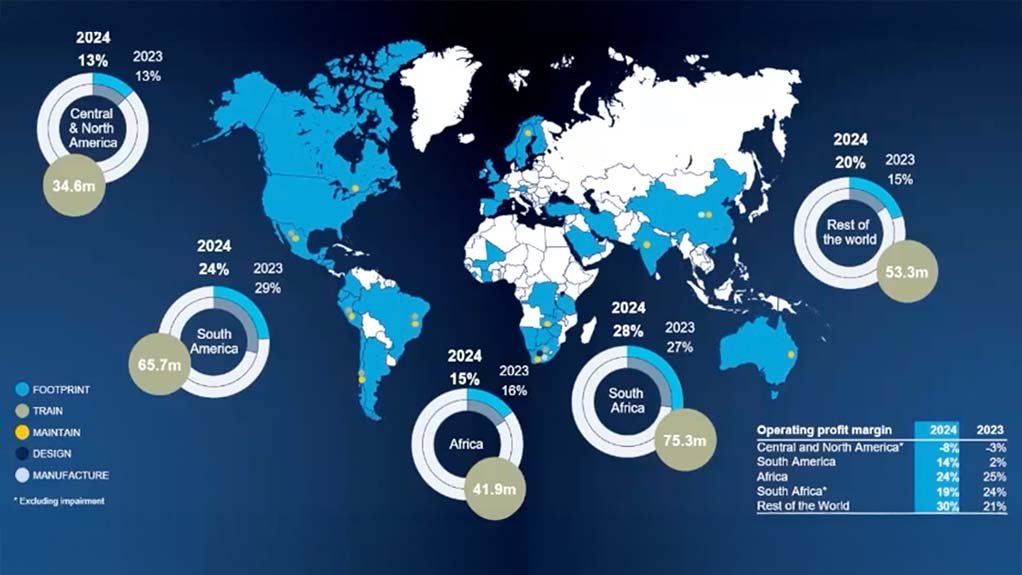

Jordaan provided a far-reaching technology update for the drilling and mechanised rock excavation technology solutions company, which was established in 1986 and listed on the Johannesburg Stock Exchange Limited in 2012. Fochville-based, Master Drilling is active in close to 30 countries.

Covered during the presentation was company technology that is being advanced in rock boring, exploration drilling, shaft sinking, tunnelling, winch safety, digitalisation, efficiency upliftment, and technical investment across a broad front.

Technological advances are taking place amid the increased number of mines that are going underground requiring accelerated access to orebodies.

“It's important that we provide solutions for fast shaft and tunnelling access to underground orebodies, dilution reduction, and grade enrichment,” Jordaan noted during the results presentation covered by Mining Weekly.

“For us to play an active role in this industry, focus on our automation, remote operation, and the robotics that we’re driving in materials handling, could make a big difference.

“There's also our understanding of what needs to happen in geophysics in exploration and in-hole data and information that's also important. How big data is treated and how value is generated from that by artificial intelligence is important,” he added.

Master Drilling finds that clients with greater access to data have a bigger capability to be able to manage their operations in a safer and a more efficient manner.

“That being said, we also see risk in the implementation of solutions that are not brand agnostic. You can't have a project anymore that's operated in India and the servers are hosted in America,” Jordaan opined.

TECH INVESTMENT

Being worked on are several raise-boring projects as well as engineering and design of a reverse circulation rig, which is required for specific shaft infrastructure construction. Engineering is also on the way for second-generation low-profile slot boring equipment.

Regarding shaft-sinking equipment, a 50 m test sink during the beginning of February is providing insight for commercialisation next year.

In tunnelling, a 5.5-m-diameter tunnel borer being advanced is heading for project mobilisation by the middle of this year, and a completed 6.5-m-diameter tunnel boring design is awaiting inquiries.

Collaboration with Komatsu is also under way to identify the right opportunity to work together.

“In terms of cut and break, we’re working in partnership with Element Six developing technology, and then also their consumables for tunneling applications, where we’re very excited about the potential of this technology as a low-energy, non-explosive method.

“If you look at reef boring, we’re busy assembling the system. We followed a staged approach where we've been successful on the milestones that we've set.

"We’ll do surface experimental testing with this unit, and then it should move to a field trial towards the end of the year. We're doing this work in collaboration with African Rainbow Minerals,” Jordaan reported.

DIGITISATION

Group company A&R’s winch proximity system confirms the identity, training and licence status of those operating the equipment. Antennas sense an approach and stop the equipment if anybody enters the centre raise, where scraper winching is being done. The market for this is expected to be around 2 000 units to 2 500 units.

“We’re also working on a secure, private, large language module (LLM), which deals with big data queries, enabling clients to optimise their efficiencies and reduce their safety exposures, so they're busy with the design of a system,” Jordaan revealed.

Meanwhile, group company AVA has made a solution available that gives users a real-time view of their operations.

Much of the processing of data was made possible by increased computing speeds and capacity, and also reduced cost, which allows for the use of LLMs and the efficiencies to process all of this data.

In conjunction with the material management module, clients have a real-time look at the their mining, stockpiling and blending in a way that maximises delivery of mined materials.

EMAIL THIS ARTICLE SAVE THIS ARTICLE ARTICLE ENQUIRY FEEDBACK

To subscribe email subscriptions@creamermedia.co.za or click here

To advertise email advertising@creamermedia.co.za or click here